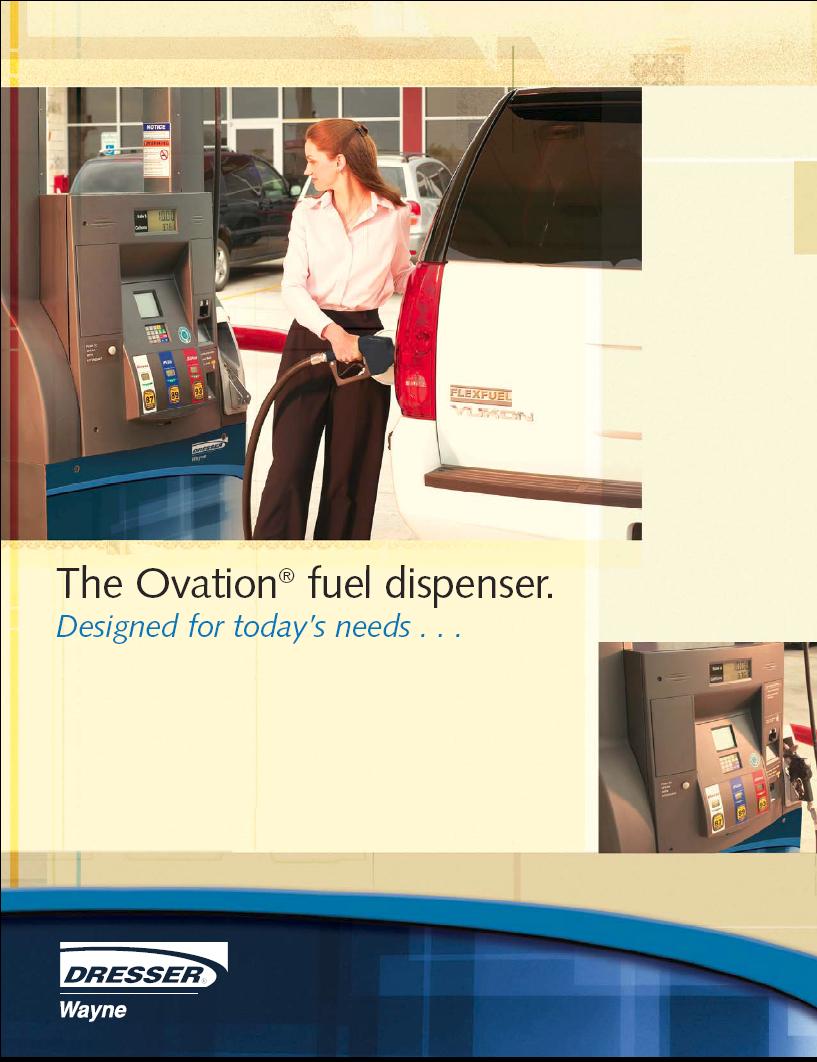

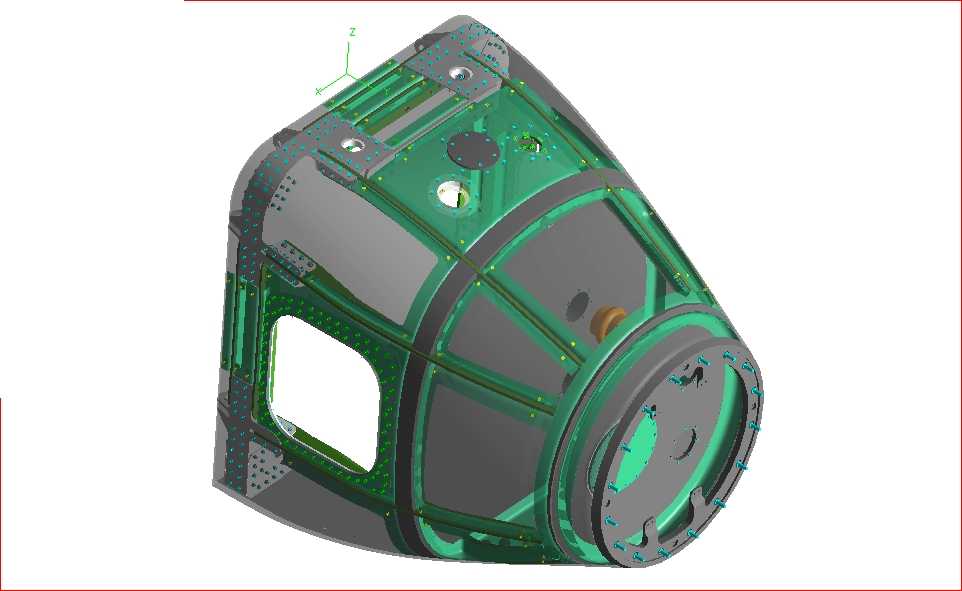

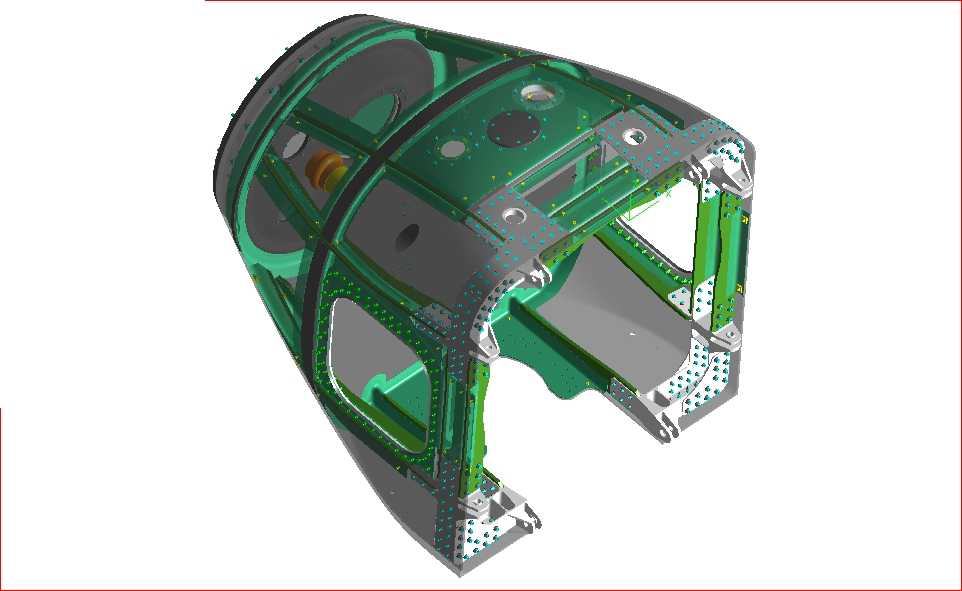

Our division was given the task of designing the main selection panel of the Ovation project. After using an old panel as a starting point, I was asked to make a few minor changes prior to an assessment of the full scope of the design process.

Since the panel was going to be much lower than the typical design, I did a quick ergonomics study of the situation. I pointed out some issues with the old design and a few preliminary solutions. With that, I was given freedom to look at our portion of the project from the ground up.

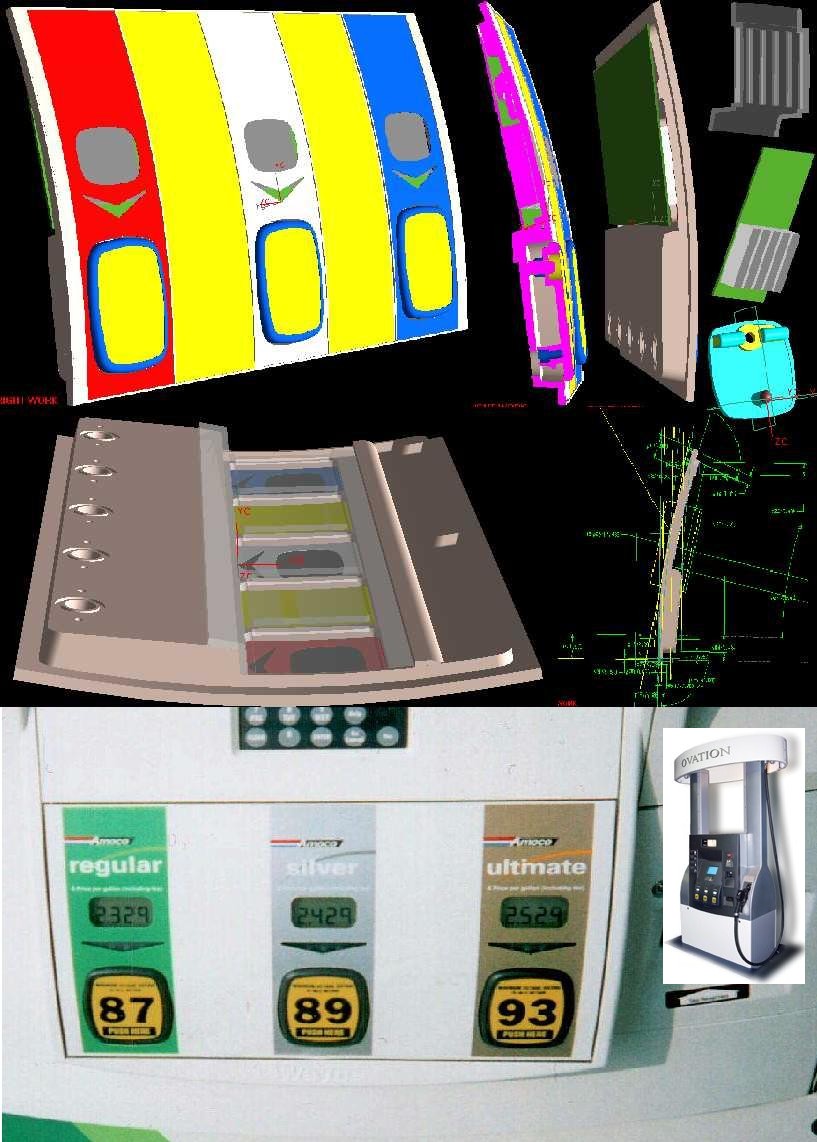

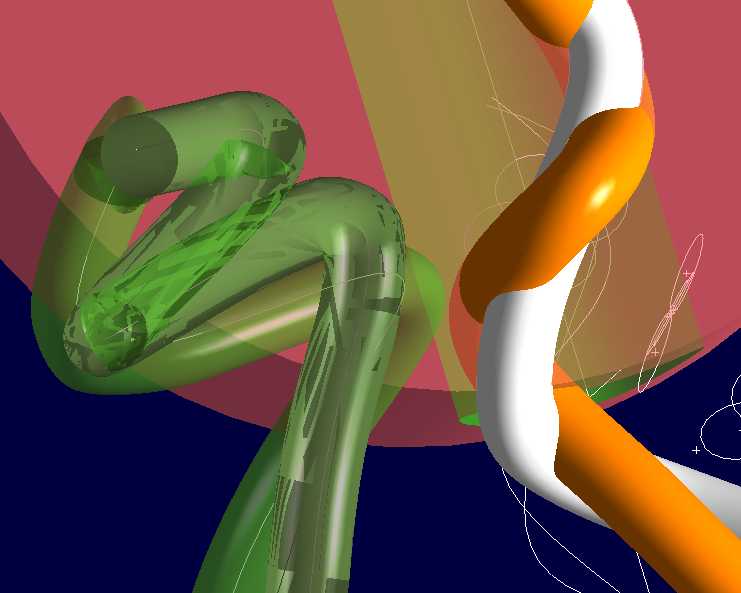

The old designs were comprised of several parts which were often tailored for each customer, in order to provide different layouts and or looks. Often LCD windows and arrows were designed for different customers. I decided that I wanted to bring the LCD closer to the front face in order to provide a good view of the LCD, at that angle, without over sizing the openings. I was also looking for opportunities to commonize parts.

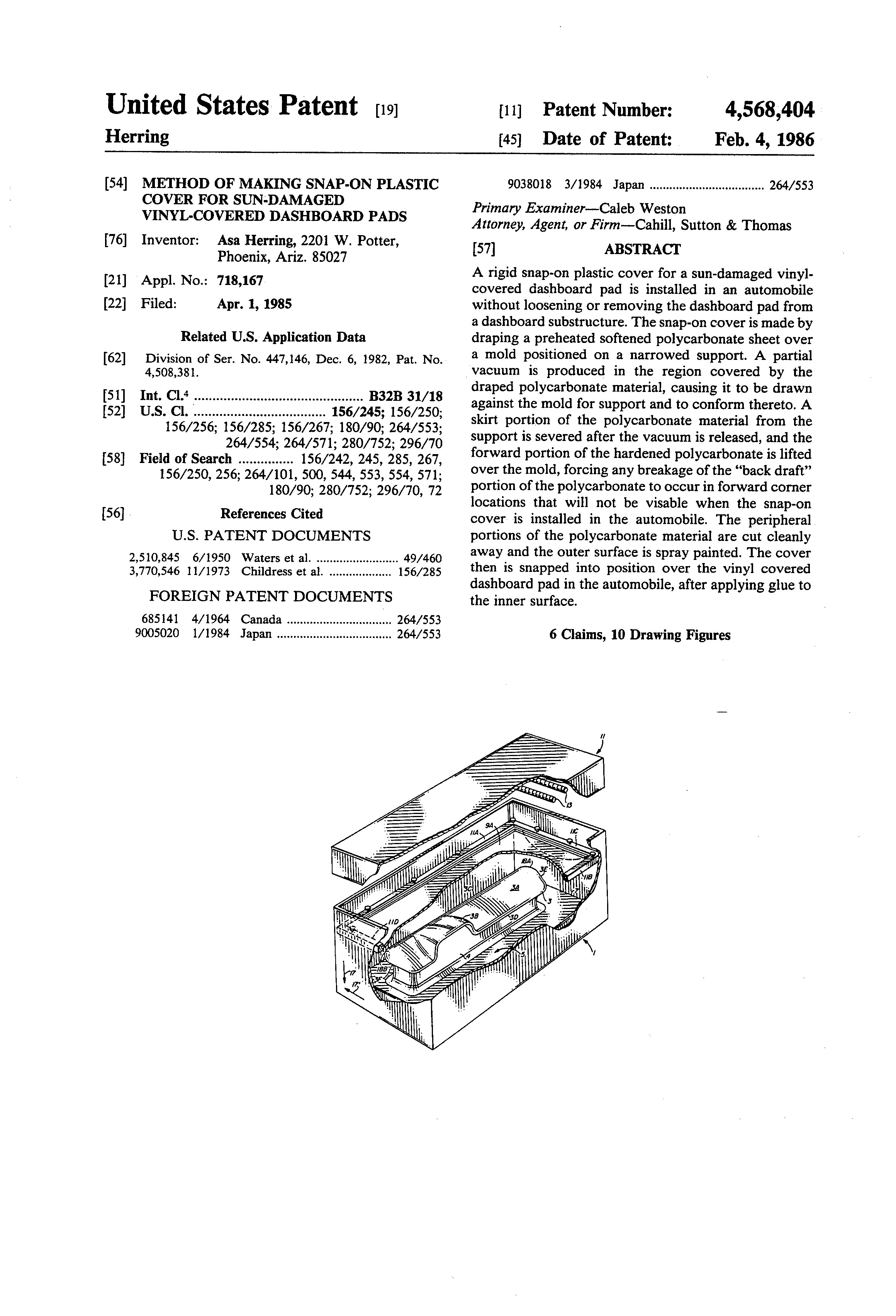

I decided to propose one big clear plastic opening instead of several individual windows and arrows. I decided that an appliqué could do the job of creating the shapes and openings while providing flexibility for each customer.

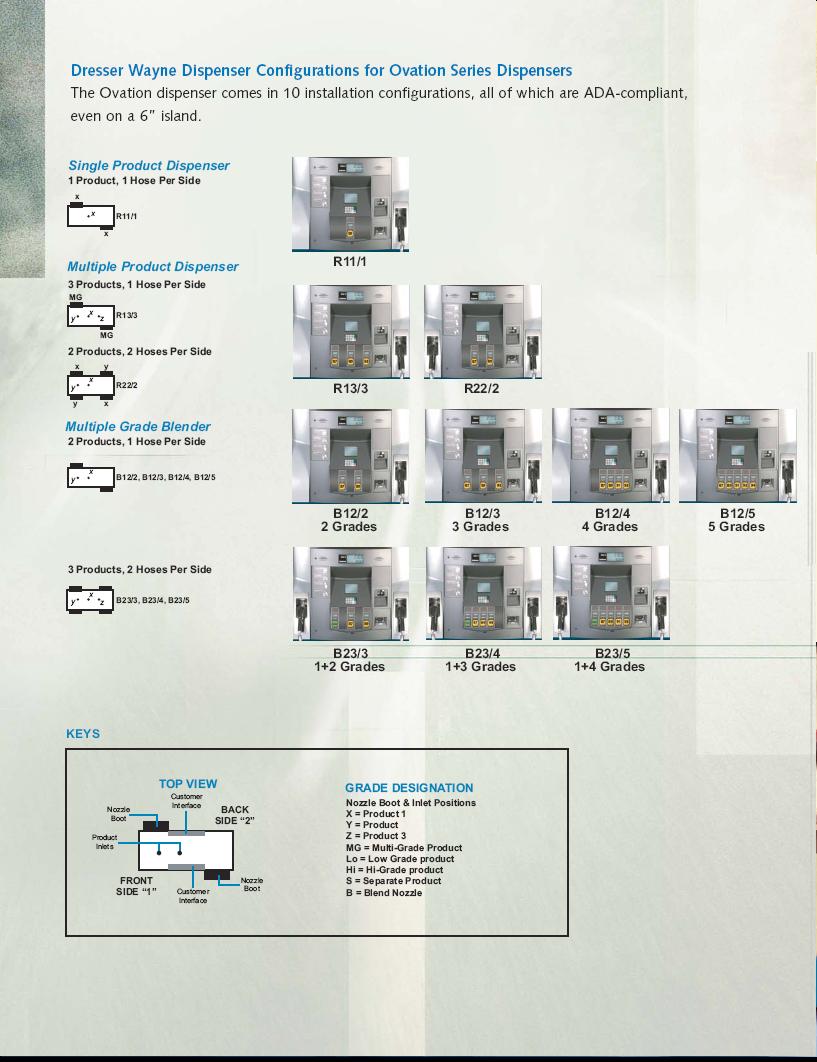

I also decided that if I created plugs, I could fill the holes of unused product selection paddles and use the appliqué to cover the plugs and the empty LCD slots as well. We then could offer custom layouts without changing the injection molded parts for each customer.

This would allow one customer to put their premium product on the far left for example, while another could put it in on the right. Customers could select any combination of 1 to 5 product selections to be offered from any one of the 5 positions.

My suggestions were accepted and I was able to produce the entire design.